Lead Time :

60 workdaysRoll Forming Speed :

20m/minWeight :

15 TonsModel No. :

YX21/41/52/62-41Shipping Port :

Xiamenpayment :

TTSolar Panel Bracket Roll Forming Machine(Economy Type)

Equipment Advantages

1.In Order To Reduce The Deformation Of The Incision,The Post-Cutting Device Of This Equipment Adopts The Method Of Shearing From Bottom To Top.

2.The Material Of The Roller Adopts Cr12(=SKD1).The Treatment Process:Rough Machining-Heat Treatment-Finishing-Electroplating.

3.Punching Die And Cutter Are Made Of Cr12Mov (=SKD11) Material,After Heat Treatment,Its Service Life Is Greatly Improved.

Material of Solar Panel Bracket Roll Forming Machine(Economy Type)

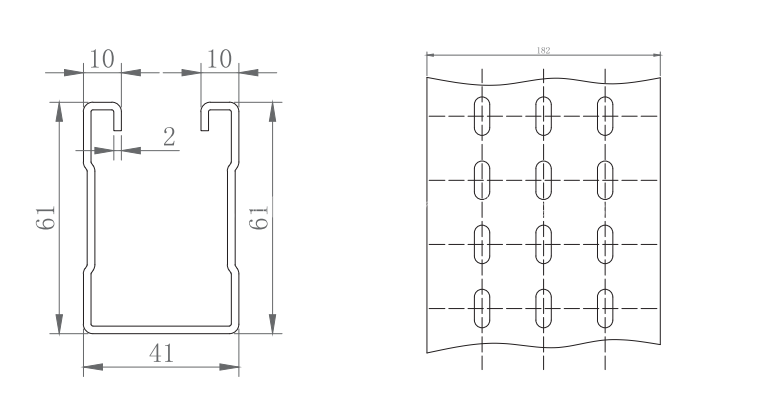

1.Material Thickness: 2.0-2.5mm

2.Applicable material:GI/GL/PosMAC

3.Material Yield Strength :235-390Mpa

4.Feeding width:142-182mm

Profile Drawing

Work Flow

Introduction to machine decomposition

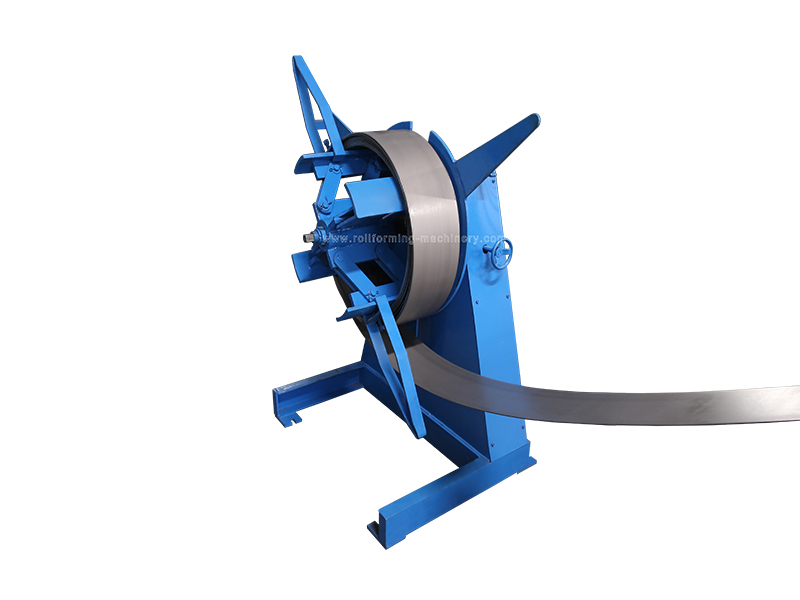

1)3 Ton Uncoiler: one set

Manual control steel coil inner bore shrinkage and stop

Maximum feeding width:300mm

Coil ID Range:508±30mm

Maximum capacity:3tons

Up Three, down Four, totally seven roller leveling device

With feeding guide rail, body frame made from H450 type steel by welding.

Shafts manufactured from 45# steel,Quenching and tempering heat treatment, hard chrome plating.

63 Tons HIGH SPEED punching machine before roll forming, equip with one set of punching model.

Punching machine four sides with safety cover and one side with open the door

By PLC system control.

Air source of the punching machine will be supplied by the buyer.

Material sending by the Servo motor for punching more accuracy.

The body frame is welded from H450 steel

Side wall thickness: Q235 t18mm ;Tie rod:ф22 Galvanized

Rollers manufactured from Bearing steel GCr15(=EN31 steel), precision machined,hard Chrome Coated;

with thickness 0.04mm,surface with mirror treatment(for longer life and anti-rust);Shafts manufactured from 45# steel,Quenching and tempering heat treatment, hard chrome plating.

Diameter=φ75/85mm,precision machined ;Gear & chain drive about 22-step to form

Main Motor=15KW ,Frequency speed control

Speed reducer motor:K series

Chain: ZIQIANG (by China TOP 1 brand DONGHUA Group)

All the screw bolts with grade 8.8 to ensure fix the machine structure tightly and long life during the machine long time running.

Product speed:12-18m/min(Including punching and cutting time)

6) Hydraulic Post Cutter

Post to cut, stop to cut,Three pieces type of cutting blade design, no blanking

Hydraulic motor: 5.5KW ;Cutting pressure: 0-12Mpa;

Cutting tool material: Cr12Mov(= SKD11 with at least one million times of cutting life), Heat treatment to HRC58-62 degree

The cutting power is provided by the independent engine hydraulic station.

Control The Quantity And Cutting Length Automatically

Input The Production Data(Production Batch,pcs,Length,etc.)On The Touch Screen ,

It Can Finish The Production Automatically.

Combined With: PLC, Inverter, Touch Screen, Encoder, etc

The Difference Between Economy and Luxury Type:

1.The Difference Between The Uncoiler

Hydraulic Uncoiler Economy Manual Uncoiler

2.The Difference Between Punching Machine

Luxury Type Economy Type

3.The Difference Between Punching Machine

Luxury Type Economy Type

4.Whether Equipped With Hydraulic Pre Cutting

Luxury Type(Yes) Economy Type(No)

Application

Solar Panel Bracket Roll Forming Machine(Economy Type) is a "photovoltaic support" for multi -functional applications for the production of bracket structure equipment related to the electrical industry. It is mostly used in the field of electrical engineering,in the fields of photovoltaic power generation, solar power generation, and optical power generation.

Our advantage

1.Over 25 years experience in roll forming industry,nearly 10 years of OEM experience for Taiwan roll forming machines and one of China TOP 3 high quality roll forming machinery manufacturers and exporters (BMS has exported to over 100 countries and regions).

2.Industry's best warranty in China 2 years parts & 2 years labor and 7*24 award winning customer service within 24 hours.

1. The warranty is 24 months after the client receives the machine. Within the 24 months, we will courier the replacement parts to the client free of charge.

2. We offer technical support for the entire life of our machines.

3. We can send our technicians to install and train the workers in the clients' factories with extra cost.

Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),loaded into container and steadily fixed in container by steel rope and lock, suitable for long-distance transportation.