Lead Time :

60 workdaysRoll Forming Speed :

15-25m/minProduction Speed :

20-25m/minModel No. :

YX83.5-500-780Shipping Port :

Xiamenpayment :

TTBIPV Boltless Seam Lock Roofing Panel Roll Forming Machine(Design for Installation Of Solar Panel)

The Advantages

1.BIPV incorporates the use of solar energy into the overall design of the building, using photovoltaic power generation module unit panels and maintenance walkway panels directly as roof panels, and in BIPV buildings, junction boxes, connecting wires, etc. can be hidden under components and pedals through relevant designs.This prevents direct sunlight and rain erosion without affecting the building's appearance.

2.BIPV photovoltaic module packaging using PVB film, PVB film has transparent, heat-resistant, cold-resistant, moisture-resistant, high mechanical strength and other characteristics, it has been maturely used in the production of laminated glass for buildings, can reach more than 50 years of service life.

3.It mainly uses water-repellent glass panels and main sinks, waterproof seals, etc. to form a roof anti-drainage system.

Material of BIPV Boltless Seam Lock Roofing Panel Roll Forming Machine

| Applicable material | Material Thickness | Material Yield Strength | Feeding width |

| GI | 0.4-1mm | 235-345Mpa | 1140mm |

| PosMAC | 0.6mm | 235-345Mpa | 1140mm |

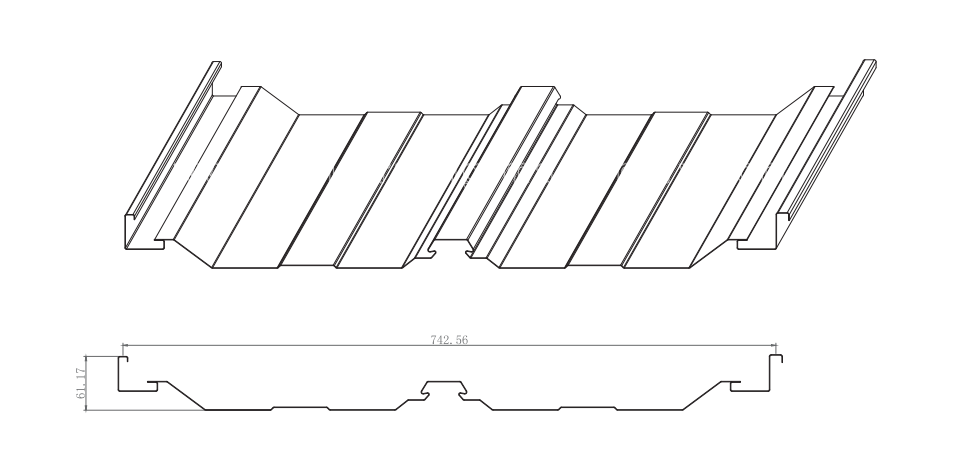

Profile Drawing

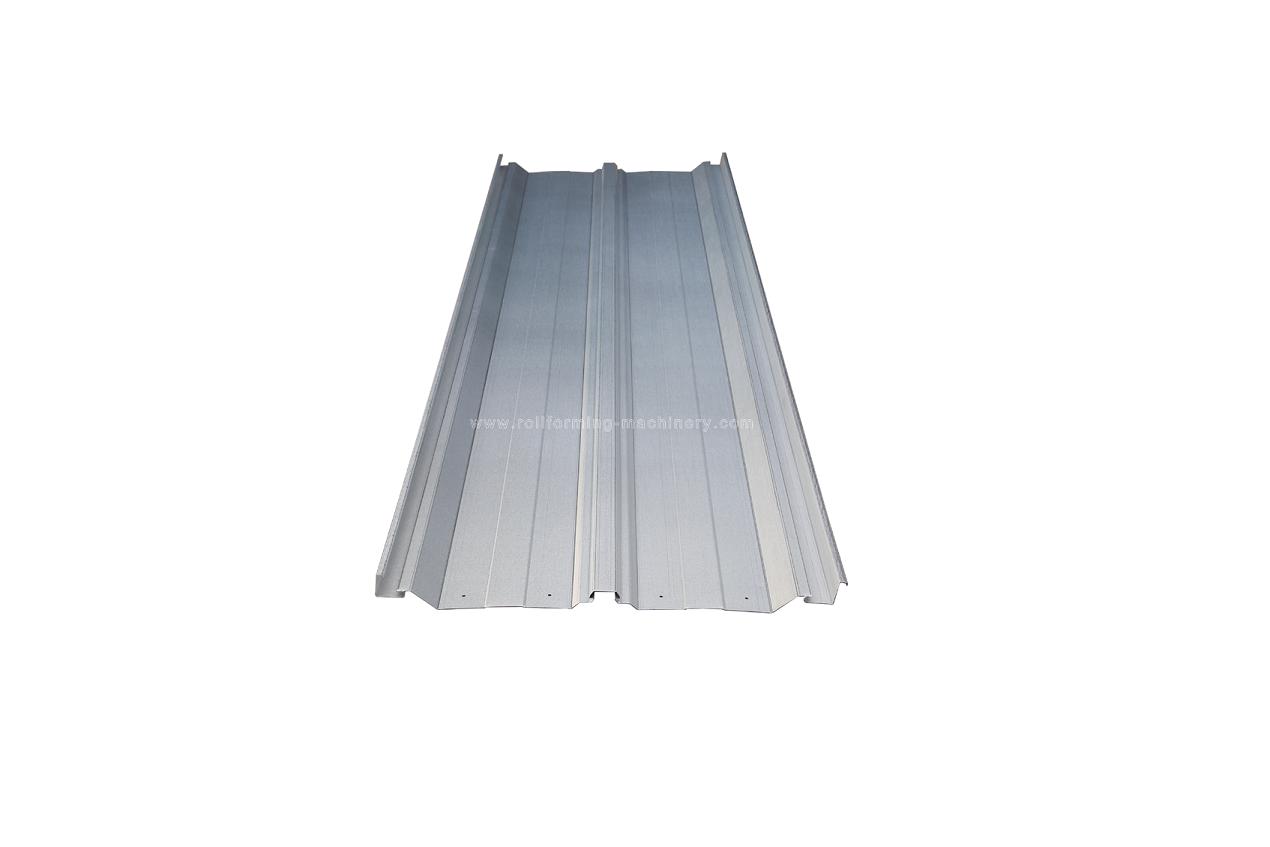

sample show

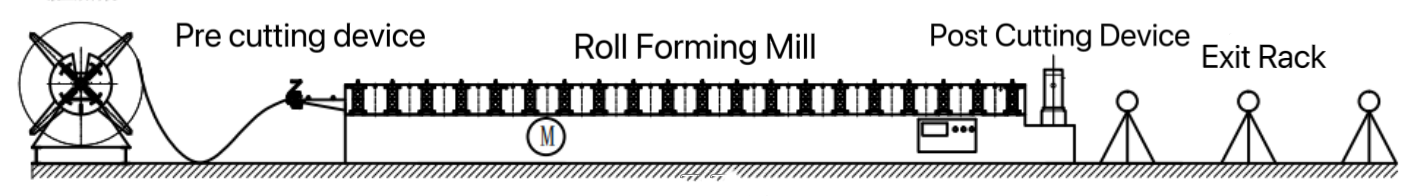

Work Flow

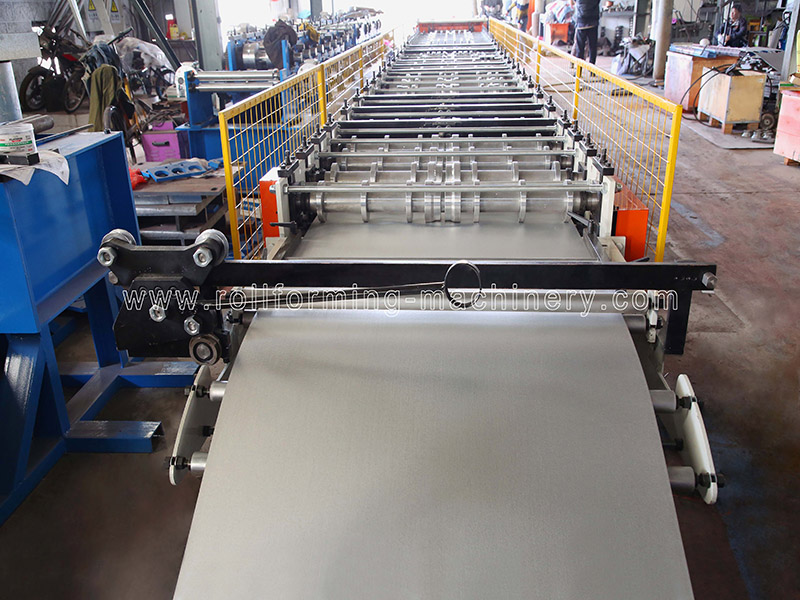

Introduction to machine decomposition

1) 10T Manual Decoiler

Load-bearing capacity:10T

Feeding Width:1250mm

2) Bend Feeding Guides Device

3) Laminating device (Duplex)

4)Roll Forming Mill

The main frame is welded with international standard H350 steel.

The side panels : Q235

Side wall thickness: 16mm

The rollers are finished with 45#,Hard chrome brushed polishing (mirror finish),The wheels are Cr12.

Shaft Diameter φ75mm

Spacer made from 45# steel, CNC lathes,Hard chrome plating treatment.

Gear & Chain drive about 30-step to form.

Motor :7.5KW+7.5KW, reducer R series

Sprocket 18 teeth, chain ZiQiang brand, Harbin bearing, tie rod hard chrome plating

All bolts, nuts and sliders are blackened

Forming speed: 0-15m/min

5)Hydraulic Post Cutting Device(Reserve the punching position)

Stop to cut, three-blade knife cutting, blanking cutting

Hydraulic station motor:5.5KW

solenoid valve: Beijing Huade

oil pump: vane pump, Shanli engineering cylinder

Cr12 mold steel wire cutting after heat treatment

6)PLC Control System

Automatic control of quantity and cut length.

Control system: PLC, inverter, touch screen (Taiwan brand),

Encoder :OMRON Button :Schneider

Cutting accuracy< ±2mm

7)Exit Rack

Application

BIPV includes photovoltaic roof, photovoltaic curtain wall, photovoltaic lighting roof, prefabricated photovoltaic wall and photovoltaic sunshade, which is currently mainly used in large-area roofs such as industrial and commercial plant roofs, rainproof carports, and large-scale building outer curtain walls

Our advantage

1.Over 25 years experience in roll forming industry,nearly 10 years of OEM experience for Taiwan roll forming machines and one of China TOP 3 high quality roll forming machinery manufacturers and exporters (BMS has exported to over 100 countries and regions).

2.Industry's best warranty in China 2 years parts & 2 years labor and 7*24 award winning customer service within 24 hours.

2、We offer technical support for the entire life of our machines.

3、We can sent our technicians to install and train the workers in the clients' factories with extra cost.

Main body of machine is naked and covered by plastic film ( to protect of dust and corrosion), loaded into container and steadily fixed in container by steel rope and lock, suitable for long-distance transportation.