Lead Time :

60Roll Forming Speed :

20m/minWeight :

13TModel No. :

CZ100-300Shipping Port :

Xiamenpayment :

T/TCZ Purlin Forming Machine(Semi-Automatic type)

The CZ Purlin Machine uses the same set of equipment. Through simple manual stepless adjustment, various specifications of C and Z Purlin can be produced.

Introduction of CZ Purlin Roll Forming Machine(Semi-Automatic type)

1.To produce different sizes, there is no need to change the roller or pad.

2.Simple operation, low maintenance cost.

3.Infinite size (any size within the range of the machine), simple size.

4.Handmade holes in any position of the board and flange.

Machine Main Components

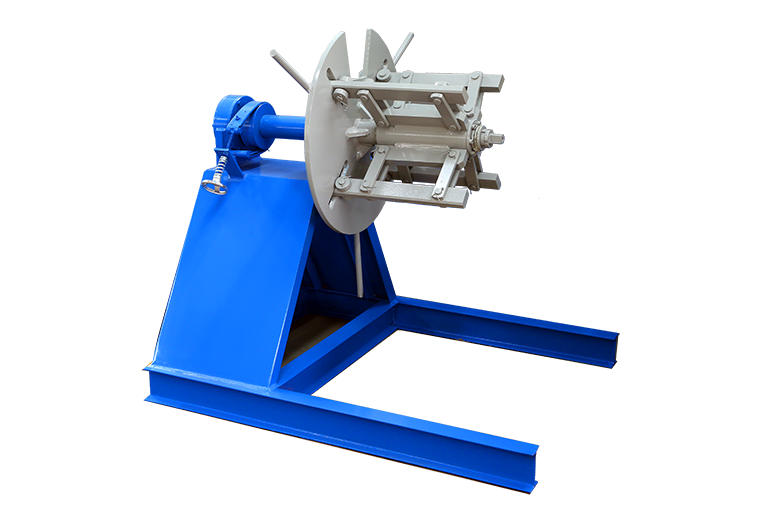

1)Uncoiler

Manual roll machine

No motivation, manually control the inner hole of the steel roller shrink and stop

MAX. Feeding width: 500mm, the inner diameter of the coil: 470mm ± 30mm

Capacity: up to 5 tons

Equipped with a 5 -ton hydraulic decoiler.

2) Pre -cutting device

The knife handle is welded with a high -quality 30mm steel plate

CZ purlin machine pre- processing machine is made of high -quality mold steel CR12 (D3 steel) through heat treatment

The knife handle is welded with a high -quality 30mm steel plate

3)Roll Forming machine

The roller use high -quality bearing steel GCR15/mold steel CR12 (= D3 steel) by the lathe and thermal treatment.

Use hard chromium coating or black treatment, with long service life. Take into the guide rail, the bracket is welded with 450# H -shaped steel.

4) Punching system

Brand: BMS Origin: China

3 cylinders (single -hole 1 cylinder, dual -hole 2 cylinder) or 5 cylinders (commonly used in the solar industry).

5) PLC control system

PLC Control System (Inverter brand: Schneider Electric/Controller/Delta,Coder brand: Koyo/Omron)

C -type purlin and Z -type purlin interchange: manual replacement

But from the C100-300 or Z100-300, the PLC system automatically changes the size: a few subtle changes on the touch screen

(Enter the required production data on the touch screen)

The machine will automatically control the quantity and cutting length.

Combination: PLC, inverter, touch screen, encoder, etc.

Performance: ≤ ± 2mm

Control voltage 24V

6) Export rack

When there is no motivation, there is a roller on it, which is convenient for the movement of the finished purlins.

Features

C to Z Purlin Changing With Following 3 Simple Operation(Finish Within 5minutes)

1.Loosen Locating Pin

2.Rotate The Adjustment Tool 180 Degree

3.Fix Locating Pin

Purlin Machine Workshop Batch Production