Lead Time :

90 daysRoll Forming Speed :

20m/minProduction Speed :

14-18m/minM Purlin (Sigma Purlin) Roll Forming Machine

Our M Purlin (Sigma Purlin) Roll Forming Machine is equipped with automatic stacker,which improves work efficiency and saves labor costs!

Introduction of M Purlin(Sigma Purlin)Roll Forming Machine

Material

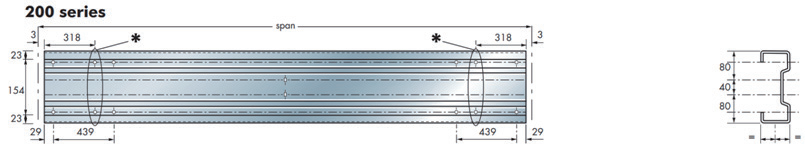

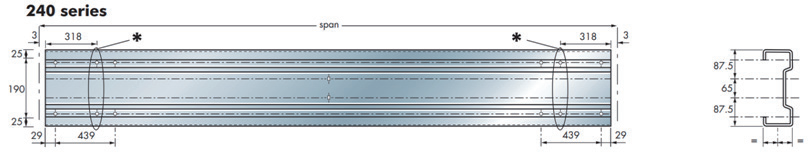

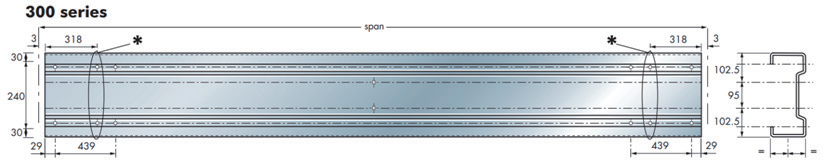

1.Effective Width:Autonomous adjustment(200、240、300series)

2.Effective Width Tolerance:±0.5mm

3.The Length Of Tolerance:±1mm

4.Inspection Thinckness:1.2-3.00mm

5.Material Yield Strength:390-450Mpa

Purlin Roll Forming Machine Main Components

Decoiler

1.Type:Mechanical Decoiler

2.Load capacity :6T

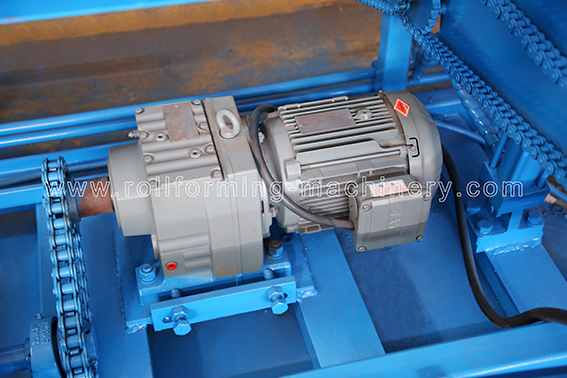

Purlin Machine

1.Roller material:Bearing steel Cr12/GCr15,with precision machined,hard chrome coated

2.Main motor hydraulic motor.

Work Flow

Hydraulic Decoiler→Feeding Device→Leveling Device→Hydraulic Pre-cutter→Punching Device→Main Roll Forming Mill(Automatic Change)→Reshaping System→Straightening Device→Post Cutter→Automatic Stacker(12M)→PLC control cabinet

Machine components

1)Hydraulic Decoiler with Coil car

2)Feeding Device

we can adjust the guiding position to adapt to the material feeding.

3)Leveling Device

Cutter structure: Flat shear (arc cutter)

Material: Cr12Mov(SKD11), heat treatment HRC 58-62.

Punching model size:a set of double hole 14*30, a set of single hole 14*30/

a set of double hole Φ14, a set of single hole Φ14

The body frame is formed by welding of H450 steel.

The roller is made of bearing steel Cr12/gcr15 precision machining, hard chrome coating;

With thickness 0.5mm, surface with mirror treatment (for longer life and anti-rust);

Shaft made of 45 # steel, quenched and tempered heat treatment, hard chrome plating.

Diameter=φ75/90mm, precision machined

Gear & chain drive about 22-step to form

Main Motor=2*11KW, Frequency speed control

Speed reducer motor: K series (Prepare by users)

Chain: ZIQIANG

All screws and bolts are rated 8.8 (cheaper factories use lower 4.8)to ensure fix the machine structure tightly and long life during the machine long time running.

Product speed: 14-18m/min (Including punching and cutting time)

Automatically control the quantity and cut length.

Enter production data on the touch screen (production batch, PCS, length, etc.)

Can be automatically completed.

Combine: PLC, inverter, touch screen, encoder, etc.

The main roller molder and hydraulic cutter must have a protective cover.

1.Profile Drawing

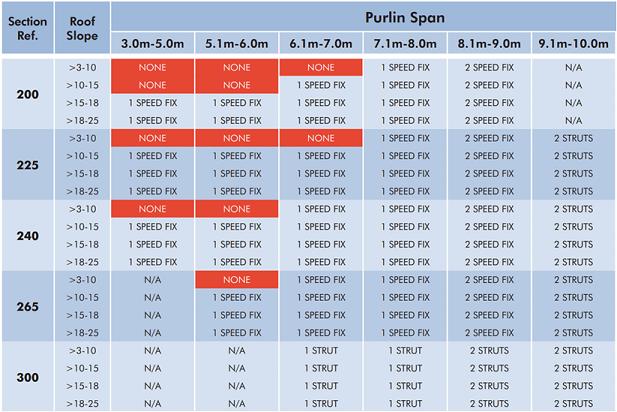

Sigma purlins have been specifically developed to minumise components,including mid span straint requirements.The purlin selections have been analyzed,by Finite Element Analysis and the minimum construction loads as dictated by EN 1991-1-6:2005.

The table below outlines the minimum anti-sag requirments for Sigma purlin,for symmetric,duo pitched roofs.It can be seen that,for the most popular spans and roof pitches,no mid span restraint is required (subject to wind uplift considerations).

2.Application

Building steel in the steel structure industry is often used in large and small housing stuctures and beam stuctures.Mostly are used in large and small factories ,logistics transportation centers,inventory warehouses,and industrial parks.

3.Our advantage

1.6 factories with 30000 m²,200 skilled workers and 6 machining centers ensure Factory Direct Price and Fast Delivery.

2.Industry's best warranty in China 2 years parts & 2 years labor and 7*24 award winning customer service within 24 hours.