Lead Time :

about 45 daysRoll Forming Speed :

18m/minWeight :

12TModel No. :

CU50-250Shipping Port :

Xiamenpayment :

T/T or L/CAutomatic C/U Purlin Machine

Introduction of Automatic C/U Purlin Machine

The advantages of the automatic change of the C -type purlin machine are as follows:

1. No need to replace the roller or pads, you can produce different sizes.

2. No need to replace the tools of different sizes.

3. Easy operation and low maintenance cost.

4.Express on any position of the side and flange side of the bars and flange.

Machine Main Components

1) C purlin machine decoiler

Manual decoiler: a set

No motivation, manually control the inner hole of the steel roller shrink and stop

MAX. Feeding width: 500mm, the inner diameter of the coil: 470mm ± 30mm

Capacity: maximum 3 tons

2)C purlin machine leveling device

Brand: BMS Original: China

3) C purlin machine hydraulic pre-cutter

3 cylinders (single -hole 1 cylinder, dual -hole 2 cylinder).

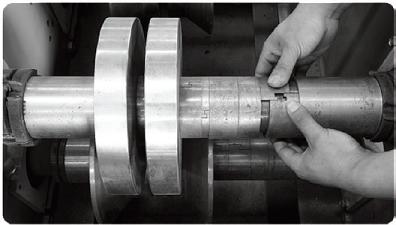

4) C Purlin machine roller

The rolling wheels are made of high -quality bearing steel GCR15, CNC lathe, heat treatment.

Black treatment or hard chromium coating is available.

Take into the material guide rail, the fuselage frame is welded with 400# h type steel.

5) C Purlin machine post-punching system

3 cylinders (single -hole 1 cylinder, dual -hole 2 cylinder).

6) C Purlin post-cutting machine

No need to replace different sizes;

Use high -quality mold steel CR12 menstrual heat treatment

The blade rack is welded with a high -quality 30mm steel plate

Pre -cut, stop punching, stop cutting

Hydraulic motor: 7.5kW, hydraulic range: 0-16MPa

7) C purlin exit rack

Un-powered,two units

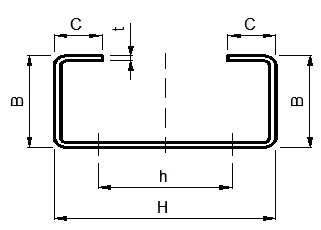

Profile Drawing

Lip(C):7~15mm

Height(B):25~60mm

optional RIB(h):1/3 of web

Matrrial Thickness:0.6~2.0mm

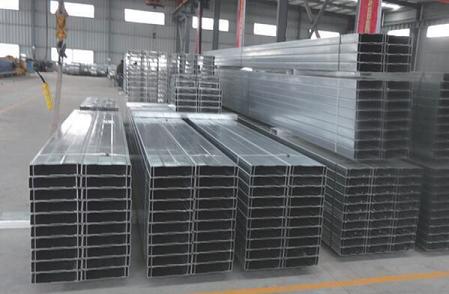

Profile Sample

Application

The finished products produced by machines and equipment are CU -type steel (purlins). They are mostly used in the supporting role of housing buildings, factory factories, and wall beams.

Features

Advantages Comparison WIth Traditional Purlin Machines

Produce Different Purlin size Without Changing Rollers or Spacers.

Motor Auto-Change Type

One-Minule Size Changing

Just input the required modle/size on the 7-inch colourful HMI,it can Auto-changing the Purlin C/U size in 1 minute,Lip/Height/Bottom width.(No need to change rollers or spacers or cutters like traditional old style machine which takes over 90 minutes for each production size changing).

Manul Wheel QUICK-CHANGE Type

(with Digit Display for Easy Adjustment)